by kpadmin | Jan 17, 2020 | Plastic Random Packing Articles

Distillation is a common application where KemFlo’s plastic random media is utilized. KemFlo’s plastic random media has many advantages including overall efficiency, corrosion resistance, durability and weight. KemFlo manufactures their plastic random media under the Kempac brand name and offer a Tri-Pack style, plastic Pall Ring and plastic Saddle packing. All three packing styles are available in three different sizes and a variety of resins. Available resins include Polypropylene, Polypropylene with glass, CPVC, PVC, PVDF and more.

Distillation is a commonly used process for separating mixtures based on differences in the conditions required to change phase of components of the mixture. To separate a mixture of liquids, the liquid can be heated to force components, which have different boiling points, into the gas phase. The gas is then condensed back into liquid form and collected. Repeating the process on the collected liquid to improve the purity of the product is called double distillation. Although the term is most commonly applied to liquids, the reverse process can be used to separate gases by liquefying components using changes in temperature and or pressure. A plant that performs distillation is called a distillery. The column used to perform distillation is called a still. A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. A refinery’s capacity refers to the maximum amount of crude oil designed to flow into the distillation unit of a refinery, also known as the crude unit.

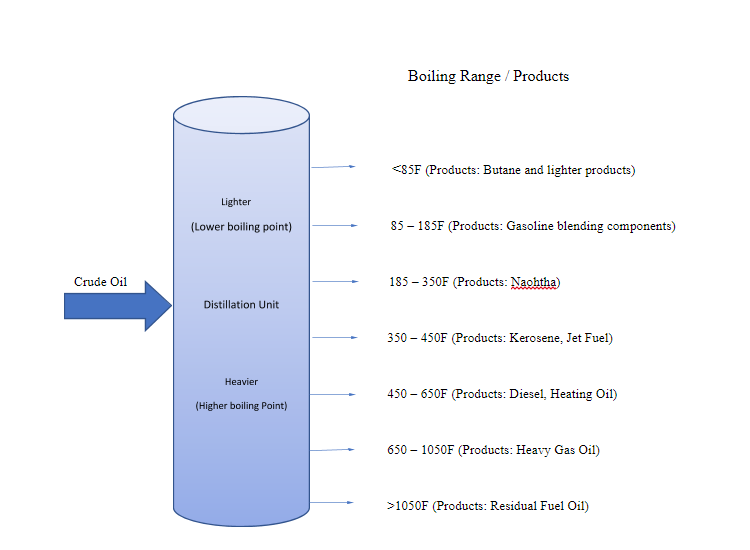

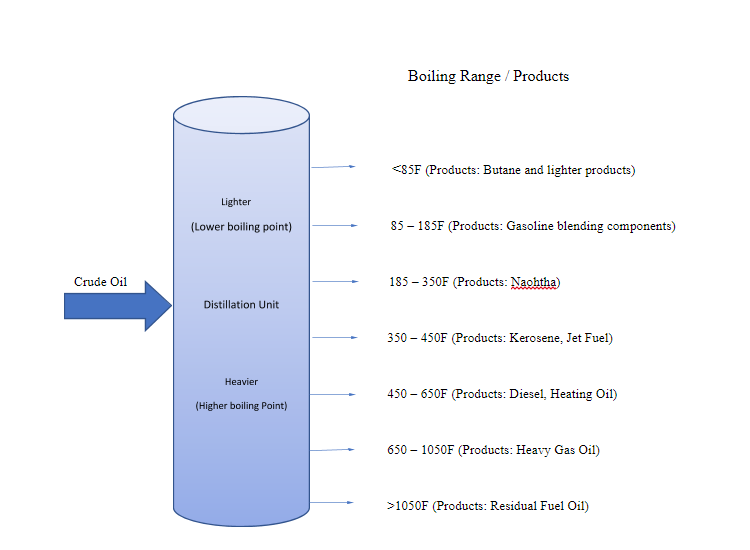

The diagram above presents a stylized version of the distillation process. Crude oil is made up of a mixture of hydrocarbons, and the distillation process aims to separate this crude oil into broad categories of its component hydrocarbons, or “fractions.” Crude oil is first heated and then put into a distillation column, also known as a still, where different products boil off and are recovered at different temperatures. Lighter products, such as butane and other liquid petroleum (LPG), gasoline blending components, and naphtha, are recovered at the lowest temperatures. Mid-range products include jet fuel, kerosene, and distillates (such as home heating oil and diesel fuel). The heaviest products such as residual fuel oil are recovered at temperatures sometimes over 1,000 degrees Fahrenheit.

The simplest refineries stop at this point. Although not shown in the simplified diagram above, most refineries in the United States reprocess the heavier fractions into lighter products to maximize the output of the most desirable products using more sophisticated refining equipment such as catalytic crackers, reformers, and cokers.

Packed bed columns may be used for distillation of vapor liquid mixtures. Random packing media provides a large surface area for vapor liquid contact, which increases the column’s effectiveness. The style of plastic random packing that is utilized in a distillation column can affect the overall efficiency of a unit so special consideration should be given to the selection of random media during the design stage of a distillation unit. KemFlo offer the Tri-Pack style packing in 1”, 2” and 3.5”, the plastic Pall Ring in 1, 2” and 3.5”, and the plastic Saddle packing in 1” 2” and 3”. Please contact Kemflo or visit our website at www.kempac-packing.com for more information on our plastic tower packing.

by kpadmin | Jan 9, 2020 | Plastic Random Packing Articles

For over thirty years KemFlo has been manufacturing high quality injection molded products utilizing numerous materials and resins. KemFlo offers complete product design, prototyping, mold making, post molding capabilities and assembly capabilities. Our custom capabilities and experience allows us to take a customer’s idea and turn it into an actual product. Kemflo’s quality assurance program ensures that all products meet or exceed our customer’s standards. Our quality assurance program involves a review process where the product is evaluated for fit and function, engineering requirements and product validation. We manufacture products for a variety of industries including Industrial, Chemical, Agricultural, Environmental and more.

One of KemFlo’s most successful products lines is their plastic random packing line which is marketed under the Kempac brand name. The Kempac family of products include three styles of plastic random packing including the Tri-Pack, Pall Ring and Saddle type. Each style of packing is available in three sizes and in a variety of resin types.

The most popular packing is the Tri-Pack style packing. The Tri-Pack style packing is one of the most efficient plastic random products on the market today. The Tri-Pack style packing is a hollow spherical packing constructed of a network of rids, struts and drip rods. Its spherical shape allows each part to roll into the packed position without forming void areas which are common to irregular shaped packing. There is no need for allowances for settling and nesting is virtually impossible. The Tri-Pack also offers reliable and predictable loading of your tower which means reliable and predictable performance. In addition to the superior geometric shape, an active surface area is vital to mass transfer. The unique network of ribs, struts and drip rods have proven to give the Tri-Pack an advantage in providing excellent wetting qualities and maintaining liquid distribution throughout the packed bed. Some suppliers claim more surface area, but surface area alone is not an indication of performance. In fact, excessive surface area can impede proper gas and liquid contact and always results in higher pressure drop which increases horsepower requirements and operating cost. The Tri-Pack offer an optimum surface area to open space ratio which results in superior mass transfer efficiency and reduced operating cost.

The Tri-Pack can be utilized in a variety of applications including air pollution, scrubbing, air stripping, absorption, distillation, extraction, humidification, dehumidification, biological filtration and more. The Tri-Pack is available in three sizes, 1”, 2” and 3.5”. KemFlo manufactures this product using only prime, virgin resins and no recycled materials are every used. Almost any injectable resin is available, but the most common resins include Polypropylene, Polypropylene with Glass, Polyethylene, CPVC, PVDF, Halar and more. All of the plastic random packing that KemFlo manufactures in polypropylene resin has been certified by NSF to Standard 61 for water treatment plant applications.

For more information in on the Tri-Pack or any of the other plastic random packing products please visit the Kempac website at www.kempac-packing.com. Whether you are looking for plastic random packing or help with your custom injection molding project give us a call.

by kpadmin | Jan 9, 2020 | Plastic Random Packing Articles

Kemflo, established in 1988, has developed a solid reputation for the design and manufacturing of high quality injection molded products. KemFlo has extensive experience in the injection molding of a wide range of thermoplastic resins both in commodity and specialty type resins. Our wide range of services in part, design, prototyping, mold design and post mold services allows us to provide our customers with a single complete source for their injection molding needs. Today Kemflo provides products and services into many different markets and has accumulated a wealth of experience in materials, design and processes. One of KemFlo’s most successful product lines is the Kempac plastic random packing line. The Kempac plastic random packing line includes several different styles of high performance packing including the Tri-Pack style, plastic saddle packing and the plastic Pall Ring.

The Kempac plastic Pall Ring is a Robust ring featuring an open wall construction which efficiently maintains liquid distribution. The Pall Ring has reinforced struts which provide additional surface area for gas and liquid contact and support the outer ring. The Kempac Pall Ring is available in 1”, 2” and 3.5” sizes. The Kempac Pall Ring is available in a variety of thermoplastic resins including Polypropylene, Polypropylene with Glass, High Density Polyethylene, Low Density Polyethylene, PVC, CPVC and PVDF. Other resins may be available as well. Please feel free to contact Kemflo for more information regarding available resins.

The Pall Ring is utilized in a variety of applications including:

- Air Scrubbing: This is a process used to clean industrial exhaust streams and gas emissions. An example would be the removal of Sulphur from a power plant exhaust system.

- Air Stripping: Air Stripping is transfer of volatile compounds of a liquid into an air stream which is then treated. This process may be used to treat contaminated groundwater.

- Distillation: Distillation is the process of separating the components or substances from a liquid by using selective boiling and condensation.

- Deaeration: The removal of air molecules from another gas or liquid, such as the removal of oxygen from liquids.

Other applications include Absorption, extraction, humidification, dehumidification, biofiltration and more.

The Kempac plastic pall ring is typically shipped in either five for ten cubic foot cardboard boxes. The boxes may either ship loose or on wood pallets. Super sacks or poly bags are also available upon request. Storage and handling of the packing filled cardboard boxes is important in order to keep the packing clean and to prevent the boxes from breaking thus the potential of loosing packing. Please note that the cardboard boxes are not designed for outside storage. Boxes should be stored indoors on level flooring and free from water damage or condensation.

Proper installation of the plastic pall ring as with any random packing is important. There are many different ways to install plastic pall rings depending on the tower size, packed bed height and the position of other internals. Typically the pall ring can installed by simply dry dumping with reasonable care. Make sure that the packing fills all of the space in the packed bed area.

For more information on Kempac’s plastic pall ring of other plastic random products such at the Tri-Pack or plastic saddle packing please visit our website at www.kempac-packing.com.

by kpadmin | Jan 9, 2020 | Top Plastic Random Packing Articles

Contaminated ground water or surface water occurs when manmade products such as gasoline, oil and chemicals get into the water and cause it to become unsafe and unfit for human consumption. Since half of the United States population is dependent on groundwater it is extremely important to protect this resource. Drinking contaminated groundwater can have serious health effects. Wildlife can also be harmed by contaminated groundwater. A good example are the pesticides and fertilizers that can find their way into groundwater or other water supplies. Other examples of sources of groundwater contamination include storage tanks which may become corroded, crack and develop leaks, Septic systems that are not maintained properly, Hazardous waste that is not properly disposed, landfill runoff, road salts and atmospheric contaminates.

One of the most efficient ways to clean contaminated ground water or surface water is to utilize an air stripper. Air stripping is the process of moving air through contaminated groundwater or surface water in a treatment system. Air Stripping removes chemicals called volatile organic compounds or VOCs. Volatile organic compounds are chemicals that easily evaporate which means they can change from a liquid to a vapor. The air passing through contaminated water helps evaporate VOCs faster and more efficiently. After treating the water, the air and chemical vapors are collected, and the vapors are either removed or vented. Air stripping uses an air stripping column to force air through contaminated water and evaporate VOCs. The most popular type of air stripper is a packed column air stripper which is a vertical tank filled with plastic random packing such as kempac’s Tri-Pack, plastic Pall Ring or plastic Saddle. Contaminated water is pumped into the top of the column and sprayed over the plastic random packing material. The water trickles downward though the spaces between the plastic random packing. Air is blown into the bottom of the column. As the air rises through the column it flows across the packing and contaminated water. The plastic random packing provides an area for the air and contaminated water to mix and helps to increase the rate of evaporation. The air is collected at the top of the column and can be released or treated while the water is collected at the bottom of the column and where it can be tested. This process can take months or even years depending on contamination concentrations and the amount of water required to be treated.

Selecting the proper plastic random packing is important when designing an air stripper. Kemflo manufactures three types of packing that should be considered when designing an air stripper under the kempac brand name. these packing include the Tri-Pack style, Plastic Pall Ring and the Plastic Saddle. The Tri-Pack is available is 1”, 2” and 3.5”. The Plastic Pall Ring is available in 1”, 2” and 3.5”. The Plastic Saddle packing is available in 1”, 2” and 3”. The Tri-Pack style is most commonly used in air stripping applications due to its unique design. The Tri-Pack is a spherical column packing that is constructed of a network of ribs, struts and drip rods. The Tri-Pack’s superior geometric shape and active surface area make it the ideal random packing for air stripping applications.

For more information about kemflo’s Kempac plastic random packing product line please visit our website at www.kempac-packing.com.

by kpadmin | Jan 9, 2020 | Top Plastic Random Packing Articles

Air scrubbers are air pollution control devices that use liquid to remove particulate matter or gases from an industrial exhaust or flue gas stream. In comparison to other air pollution control devices, scrubbers are a very efficient way of removing solids, mists, and gases while also providing cooling. They are also capable of handling volatile gases safely. However, scrubbers suffer from high levels of corrosion and produce slurry waste streams which are less convenient for recycling and disposal.

Scrubbers are devices that use a liquid to capture and remove pollutants. Through a nozzle or orifice a scrubbing liquid is introduced into the gas stream. The droplets capture the dust particles. This increases the size and mass of the particles, making them easier to collect in a filter or separation process. The scrubbing liquid absorbs and neutralizes gaseous pollutants. Suspended liquid is typically recovered in mist collectors and recycled through the system.

A key parameter in the design of scrubbers is the liquid-to-gas ratio. It is commonly expressed in gallons per minute (gpm) of liquid divided by actual cubic feet per minute of gas. This ratio is determined by the solubility of the gas pollutants, the amount of pollutants and particulate matter in the gas stream, and the mass transfer characteristics of the tower. Increasing the liquid to gas ratio increases the collection efficiency of the system, so finding the optimum ratio is important for balancing performance with operating costs.

Packed bed or packed tower scrubbers are systems which contain one or more layers of packing material to increase gas-liquid contact, such as Kempac’s Tri-Pack style, plastic pall ring, or plastic saddle packing. Gas streams enter in the bottom of the chamber and flow upward or horizontally through the packing as scrubbing liquid is distributed uniformly to the packing material. Once through the packing, cleaned gas passes through a mist eliminator while the waste liquid/slurry falls to the bottom by gravity. Some packed towers designed for

Packed bed scrubbers are primarily gas absorbers and are the most effective scrubbers for treating gas streams with gaseous pollutants. They can collect solids, but are not often used for this purpose because wet dust collecting in the beds would require unreasonable maintenance. One of the key design considerations for packed scrubber towers is the selection of the type of random packing and the material or type of resin. Kemflo offer several styles of plastic random packing in a variety of resins to meet your application. Kempac plastic random packing is available in a Tri-Pack style packing which is available in 1”, 2” and 3.5”, a plastic pall ring packing that is available in 1”, 2” and 3.5” and a plastic saddle packing which is available in 1” 2” and 3”.

There are multiple styles of scrubbers to consider. Stationary or enclosed scrubbers are housed in their own building or enclosure. These are typically used to treat process exhaust gases from industrial waste streams before they are released into the atmosphere. Portable scrubbers are small units used for local cleansing and cleaning applications. In addition to small size, they may have wheels or handles to make them easier to transport. Skid or base plate mounted scrubbers are designed to be placed on a skid or plate positioned on the floor. These scrubbers frequently contain transport features such as forklift slots for movement around a facility. Trailer or truck scrubbers are mounted on a trailer or truck for mobile spot dust or fume abatement.

Performance specifications are the ratings assigned by a manufacturer that describe the scrubber’s performance. These are the specifications most important for industrial buyer to consider when selecting a suitable scrubber for their application.

- Airflow or gas flow rate defines the acceptable flow rate or range of flow rates of the gas stream through the scrubber, measured in cubic feet per minute (cfm).

- Liquid or water flow rate defines the intended flow rate or range of flow rates of the scrubber liquid in the system, often described in gallons per minute (gpm). It may be given as a liquid-to-gas ratio (L/G). It determines the amount of water used by the scrubber, which will have a large impact on the operating costs of the system.

- Minimum particle size filtered indicates the minimum diameter of particulate matter that a dust collector is capable of capturing, measured in micrometers (µm). This rating effectively defines the range of capability of the collection device.

- Efficiency, collection efficiency, or capture rate defines the percentage of particulate matter and/or gaseous pollutants in the filtered gas stream that is effectively removed by the scrubber. Efficiencies can vary widely for different types of scrubbers and different gas streams.

In addition to performance criteria, there are other parameters to consider when selecting scrubbers for a particular application. These include material compatibility and operating temperature.

- Material compatibility – It is important to ensure the materials used in the construction of the scrubber are compatible with the chemical (acidity, reactivity) and physical (abrasivity) properties of the gas stream. Applications where the scrubbing liquid contains additional chemicals or substances may make it necessary to use specialty materials with high corrosion or chemical resistance.

- Operating temperature – Although scrubbers are often designed to provide cooling or quenching of hot gas streams, these devices still are limited to a certain range of temperatures, above or below which they may not operate effectively.

For more information on Kempac plastic random packing product line including the Tri-Pack style, plastic pall ring or plastic saddle packing please visit our website at www.kempac-packing.com.