About Us

Kemflo Canada, established in 1988, has developed a solid reputation for the design and manufacturing of quality injection molded products. Kemflo is a ISO 9001 certified company with over 50 years of experience in injection molding and manufacturing. We have valued knowledge and experience in a wide range of Engineered Thermoplastic Resins. Our engineering is application specific to provide our customers with the most cost effective solutions. Our commitment is to provide our customers with value added services in quality and on time delivery. Kemflo provides products and services into many different markets and has accumulated a wealth of experience to better service their customers. Today Kemflo facilitates an 100,000 square feet operation.

Kemflo offers complete design and engineering services. Our engineering staff utilizes the latest technology to provide our customers with the best engineering solution. By utilizing tools such as our 3D printer our engineering staff can build prototype molds that can be evaluated for fit form and functionality. KemFlo has extensive mold design and mold making experience which allows us to provide customers with quality cost effective tooling solutions.

Our process knowledge covers a wide range of thermoplastics resins. We specialize in processing rigid and flexible PP, PVC, CPVC, PVDF, PFA, as well as other types of engineered resins. KemFlo offers post molding capabilities to support our injection molded products. Post molding capabilities include ultrasonic welding, hot stamping, heat insertion, machining and special packaging. Post mold capabilities are vital in providing customers cost effective solutions to manufacture products competitively.

Kemflo has heavily invested in their automated assembly capabilities to ensure each product is perfectly assembled each and every time. We offer custom engineered solutions for automated assembly techniques along with customer packaging.

Quality is our primary goal at Kemflo so our quality assurance program is a key part of our manufacturing process. Kemflo quality assurance program starts when a product is first introduced. A review process is conducted whereby the product application is evaluated for engineering requirements and product validation. This allow us to determine proper material selection, testing requirements and the total cost of manufacturing. We are committed to meeting the quality objectives and standards expected by our customers. Products are produced under the guidelines and certification requirements set out by industry standards.

In addition to manufacturing custom and private label products, Kemflo manufactures the AIK tank accessory product line and the Kempac plastic random packing product line. The AIK product line consist of a variety of tank accessories for the agricultural, industrial and chemical industries. The AIK product line including tank manway covers ranging from 16” to 22”, screw caps, vents, bulkhead fittings, poly plugs and flanged connections. For more information regrading the AIK product line please visit www.kemflocanada.com.

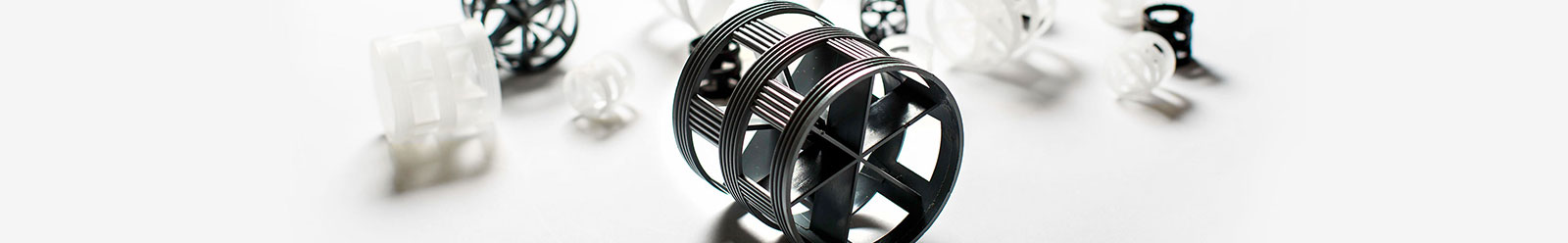

Kemflo offers a complete plastic random packing line under the Kempac name. The Kempac product line includes three different styles of plastic random packing in three different sizes. Kemflo manufactures a Tri-Pack style packing, Plastic Pall Ring and Plastic Saddles. The Tri-Pack style of packing is one of the most efficient plastic random packing products on the market. The Tri-Pack is a spherical column packing that is constructed of a unique network of rids, struts and drop rods. The Tri-Pack has a superior geometric shape that offers reliable and predictable performance. The plastic Pall Ring is a robust ring style packing featuring an open wall construction which maintains even liquid distribution. The plastic Pall Ring also has reinforced struts that provide additional surface area for gas-liquid contact. The plastic Saddle packing consist of serrated edges that promote high mass transfer rates through effective liquid surface renewal.